Description

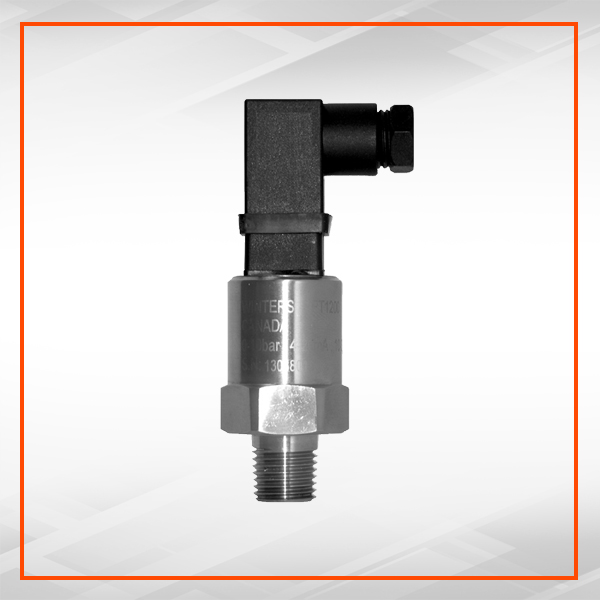

• Cost effective and reliable

• Uses diaphragm sensor

• Easy to read dial instrument eliminates the accumulated errors of two instruments installations

• High operating pressure upto 200bar

• Differential pressure range upto 7 bar

• Indicating mechanism isolated from pressure chamber

• Wide application in air, gas and liquid media

• Reed contact switches optional

• Zero migration between high and low pressures

• Only switch is also available.

Applications:

• Monitor filter conditions, set filter by-pass, or initiate filter cleaning cycle. Determine obstructions in process lines. Check condition of pumps, heat exchangers,

and other processing equipment. Adjust flow rates in piping systems. Monitor liquid levels in storage tanks

Dial Size

●2.5″(63mm), 3.5″(80mm), 4”(100mm)

●4.5″(115mm) & 6”(150mm)

Pressure range

●0.25 upto 7 bar (5 upto 100 psi)

Case

●Stainless steel case or flange

Working pressure

●200 bar / 3000 psi

Body Material

●316 stainless steel, aluminium or brass

Media Temperature

●80 C/175 F

Wetted parts

●Diaphragm, ceramic magnet, SS 304 spring

Accuracy

●±2.0% (Ascending)

Connection

●1/4″, 1/2″, 3/8″ in NPT, BSP, BSPT

Operating principle

●Magnetic coupling with a rolling diaphragm sensor

Seals

●Buna-N (Standard ) or Viton

Switch

●SPST or SPDT, one or two. Switches are field adjustable. The set points can be increased or decreased externally with a simple screwdriver adjustments. When two switches are used, either switch can be adjusted independently.

Porting

●In line (standard), Back or bottom on request

Migration of media

●Zero migration between high and low pressures

Protection

●IP 65

Window

●Glass, Acrylic or Toughened glass

Options

●Glycerine filling, maximum adjustable pointer, dual scale,

●DIN plug strainer in (+) connection

●Other connection size available

●Other internal parts in Aluminium, or SS-316 as per the body