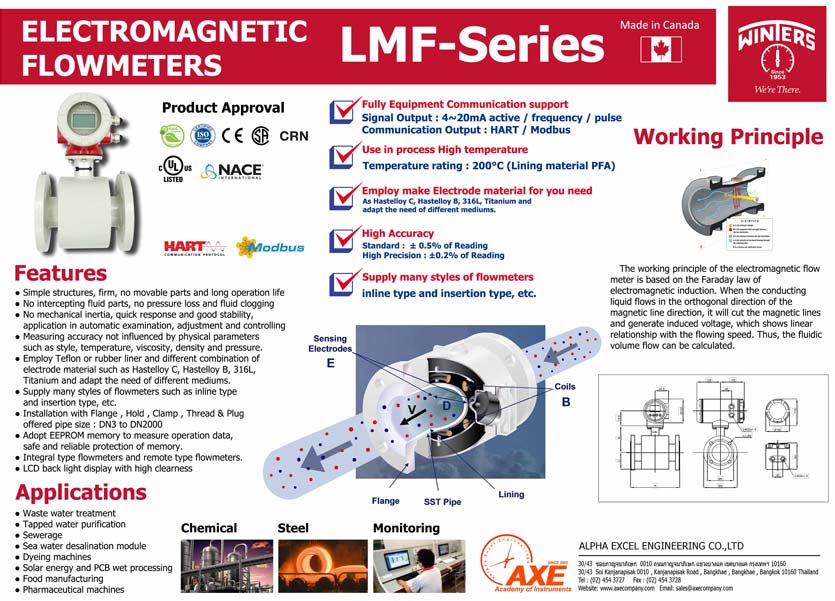

Description & Features:

• Field liquid fillable, phenolic solid front blow-out back safety case

• Stainless steel full rotary movement for longer life

• Micrometer pointer for ease in calibration

• Under & Overload stops

• 316L stainless steel, Monel wetted parts

• Designed for sour gas applications requiring NACE Standards MR 0175-2002

Applications:

• Used where operator safety is a must

• Ideally suited for process, chemical and petroleum industries

• Highly corrosive media

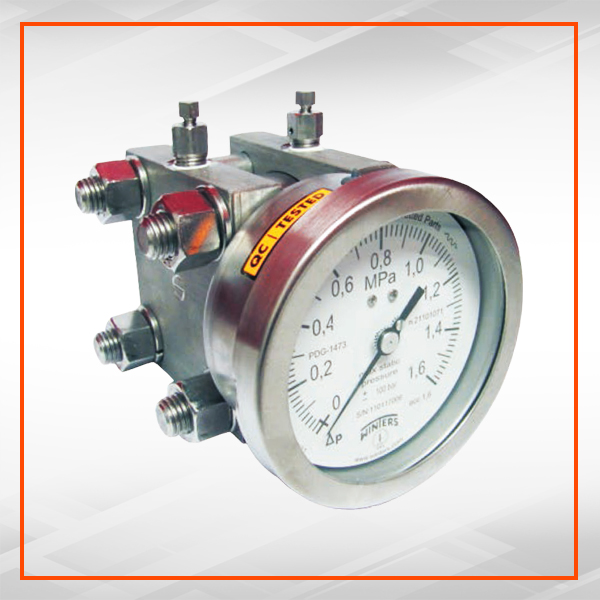

Dial Size

●4.5″(115mm) white aluminum

Pressure Range

●Vacuum to 0…20000 psi (0…1380 bar)

Case Material

●Engineered reinforced thermoplastic, black impact resistant with satety blowout back plate, solid front, integral back flange

Solid Wall

●Phenolic

Lens Material

●Tempered glass

Welding

●TIG

Protection

●IP 65

Working Pressure

●Maximum 75% of full scale value

Over-pressure Limit

●25% for pressures up to 1500 psi/kPa,

●15% for pressures 1501 to 8700 psi/kPa,

●10% for pressures above 8701 psi/kPa

Ring Material

●Phenolic

Pointer

●Aluminum black adjustable

Bourdon Tube

●316Lstainlesssteel

Movement

●304 stainless steel

Socket Material

●316 stainless steel

Connection

●1/4″, 1/2″ in NPT, BSP, BSPT

Gasket Materials

●Buna N (Silicone rubber option)

Ambient Temperature

●-40°F to 200°F (-40°C to 93°C) dry /

●-4°F to 150°F (-20°C to 65°C) glycerin-filled

Process Temperature

●-40°F to 200°F (-40°C to 93°C) dry /

●-4°F to 150°F (-20°C to 65°C) glycerin-filled

Accuracy

●±0.5% ANSI / ASME Grade 2A

Options

●Silicone filled

●Use no oil

●Oxygen Cleaning

●Stainless steel tag number plate

●Calibration Certificate

●Material Certificate

●Safety glass + Silicone filled