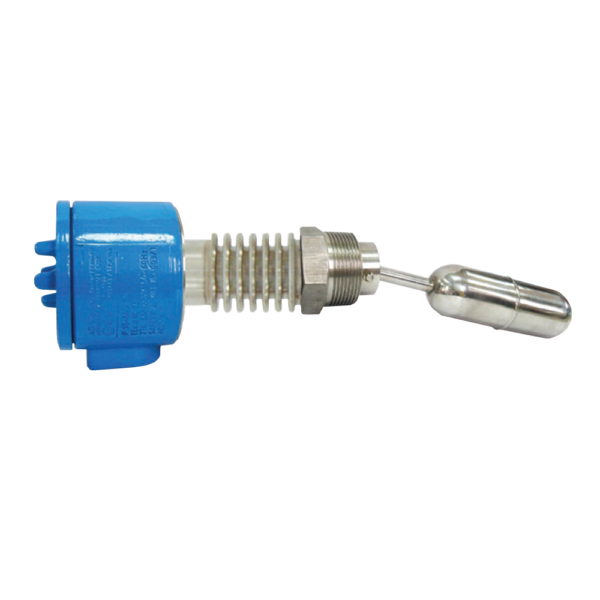

The purpose of the rotary paddle level switch is to detect the presence of solid/powdery material in most kinds of tanks, bins and containers. The unit is usually located through a bin wall at the top, middle or low level of a bin. During normal operation (no material present) a synchronous motor rotates the paddle at RPM. When this paddle rotation is impeded by material, surrounding the paddle, motor will stall and cause the Micro-switch to change state

(indicating an alarm or control).

• Plastics and synthetics

• Chemicals and fertilizer

• Pharmaceuticals

• Food and beverage

• Agriculture and fodder mills/depots

• Cement as well as ceramics

• Power plants

• Various incinerators

• Rugged sealing ring prevents dust from infiltrating the housing body along the shaft.

• Adjustable torque.

If the rotary paddle encounters overloading, the motor will automatically shut down the motor to prevent damage to the inner mechanisms and extend motor life.

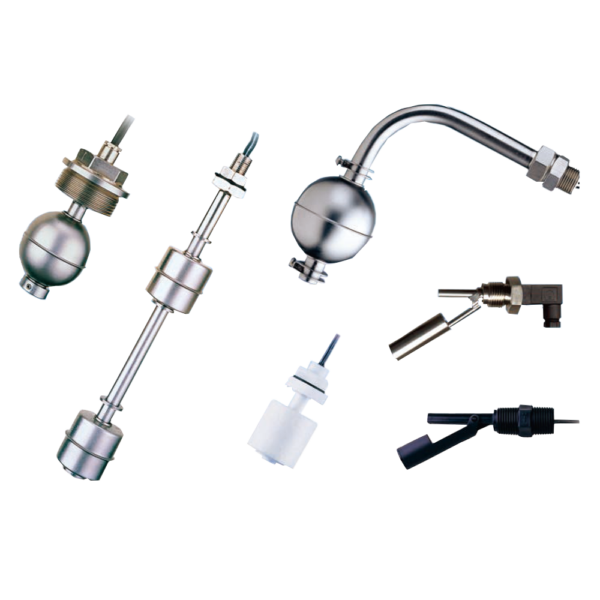

• Very suitable for small tanks and low density materials

• Adjustable and extendible shaft models available

• A wide variety of paddles are available