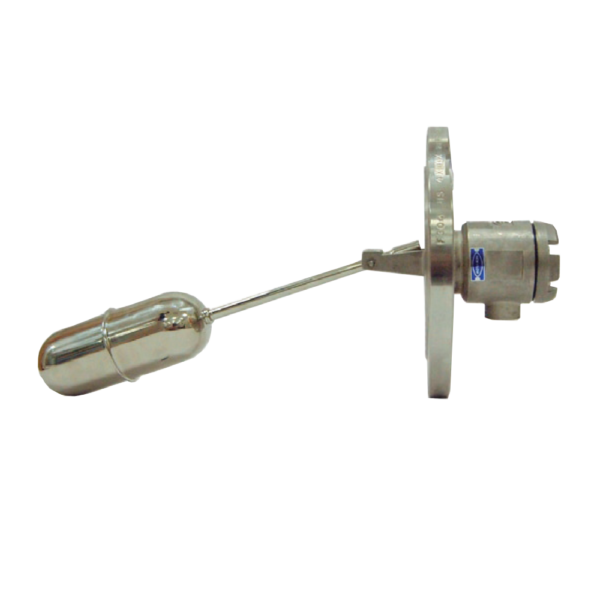

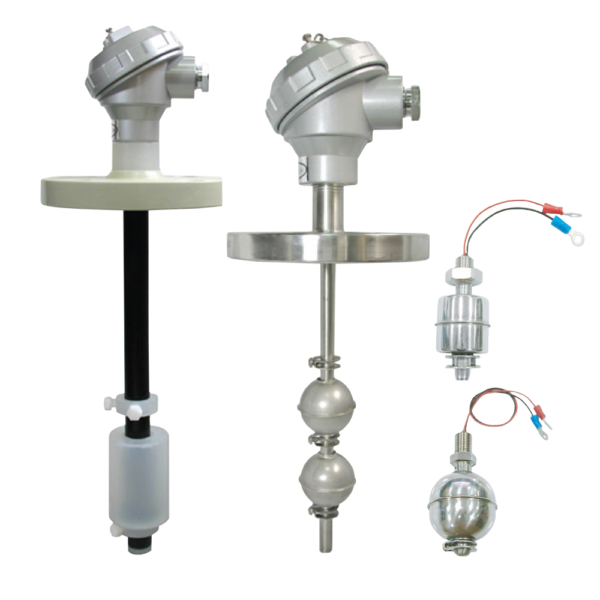

The single unit or multiple reed switch units are housed tightly in stainless steel or engineering plastic stem, and the permanent magnet is sealed into the middle of the specified float

ball(s). You can mount the float ball to penetrating through the stem, then the liquid buoyancy will deliver the float ball up and down at the specified position by graduating rings.

When the float internal magnet approaches the reed switch, it will actuate the reed switch contact point to create an open or close circuit. We can apply such on-off output signals to reach liquid level controlling and monitoring purpose.

The figures below show the float orientations on N.O. (Normal Open) and N.C. (Normal Close).

Shipbuilding Industry, Generator Facilities, Petrochemical Industry, Food/Beverage Industry, Waste Water/Water Purified Facilities, Electronic Industry, Dyeing and Finishing Industry, Chemical Industry, Rubber/ Plastic Industry, Hydraulic.

• Multiple points measuring, multiple level points could be for custom-made.

• Employing the magnet to actuate the reed switch requires no power. Life expectancy of each contact can reach up to 2 million times.

• All output signal wiring are simplified in same junction box (housing) to economize the external wiring construction.

• FC(D) type magnetic float level switches are more cost- effective than other level switches in terms of multiple points.

• The housing protection is at least IP65.

• Rugged construction and multiple options for materials from engineering plastics as PVDF, PP, PVC, and stainless steels such as SUS304, SUS316, float switches can be applied to versatile applications in chemical corrosion of acidity and alkalinity liquid, solvents or oil fuels.

• The reed switch and lead wire are isolated with liquids absolutely. All stainless steel switches are applicable to high pressure and high temperature environment.